Ball valves stand out for their durability and reliable shutoff performance, even after extended periods of inactivity. They excel in critical shutoff applications, often surpassing the performance of globe and gate valves.

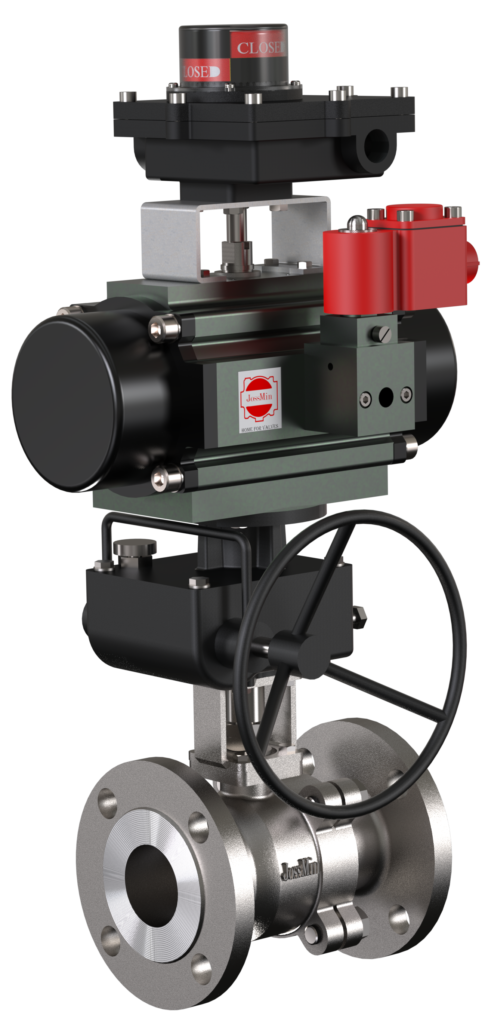

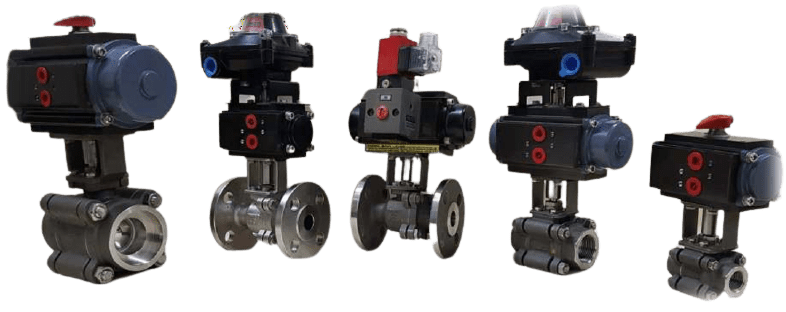

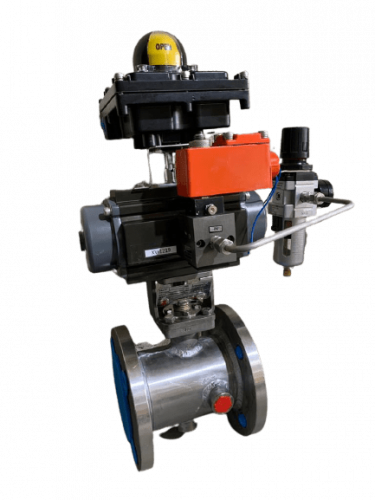

At JossMin, we adhere strictly to ASME standards in the production of Shut-Off, Control, and Multi-Position Ball Valves. Our Electro-Pneumatic Two Way Ball Valves, equipped with a Pneumatic Rotary Actuator, Solenoid Valve, Position Indicator, and AFR, offer seamless automation. Meanwhile, our Manual Ball Valves, available with Gearboxes or Levers, provide manual control options.

Our valves boast a blow-out-proof stem and antistatic ball as standard features. We offer various end connections to ensure compatibility with diverse pipelines. A Belleville washer, secured by gland nuts, guarantees zero leakage from live loading. Our valves’ components undergo ultra-finishing to enhance seal life and deflect flex seats. With a multi-sealed stem and a double gasket, we ensure a secure body joint sealing that prevents atmospheric leakage and protects against pipeline stress.

Each valve is manufactured, assembled and tested in-house to uphold the highest quality standards. For added safety, our valves are also available in a fire-safe design variation.

Explore JossMin’s extensive range of valves, including electro-pneumatic ball valves, 2-way ball valves, manual ball valves, and automated ball valve actuators. Discover segmented ball valve options, actuator ball valves, and more, all meticulously crafted for precision and durability.