Enhance Shut-Off Performance with JossMin’s Butterfly Valves

Butterfly valves are a reliable choice for applications requiring standardized shut-off. With a low-torque rotation of 90 degrees, they offer cost-effectiveness and lightweight design, making them popular among operators. Butterfly valves are categorized into three main types: Zero Offset or Centric, Double Eccentric or Double Offset, and Triple Eccentric or Triple Offset.

JossMin offers Centric and Double Eccentric Butterfly Valves that meet ASME Standards. These designs ensure easy actuation across all torque levels and provide a superior seal when closed. Our valves are available in a wide range of materials, offering versatility in the Universal Wafer Design and various end connections.

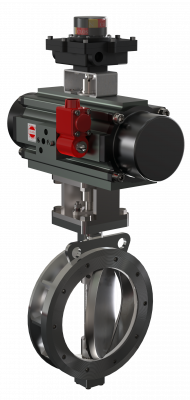

For corrosive mediums, we provide PFA/FEP lined options, while our Metal Seated Butterfly Valves with electro-pneumatic automations are suitable for high-temperature or slurry media operations.

Choose JossMin for exceptional Butterfly Valves and Valve Automations, optimizing performance for diverse industrial needs.

| Construction & Design | |

| Centric | Eccentric |

| Metallic Flap Split Body | Double Offset |

| Lined Flap Split Body | Metal Seated |

Variable End Connections / Ratings |

Universal Wafer / PN 10, 16 |

Tri clover end / PN 10, 16 |

| Slim Body / PN 3, 6, 10 |

Weld ends – Orbit-weld / PN 10, 16 |