Experience Optimal Tank Flushing with JossMin’s Flush Bottom Valves

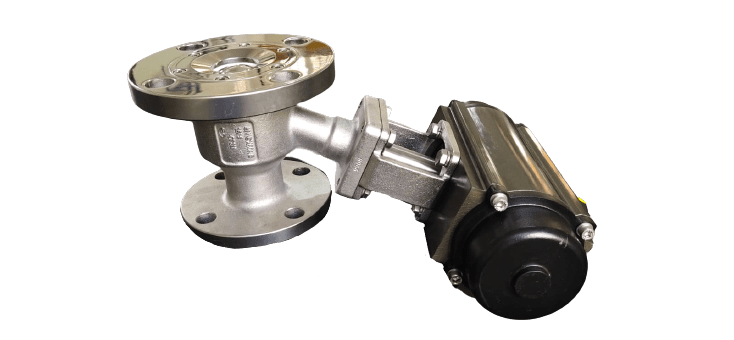

Flush Bottom Valves, also known as Reactor Bottom Valves or Tank Bottom Valves, are designed to excel in the critical process of tank flushing. By positioning these valves directly at the bottom of reactor tanks, efficient removal of materials is ensured. These valves are specifically engineered to withstand the pressure and heat generated by reactors, providing reliable performance.

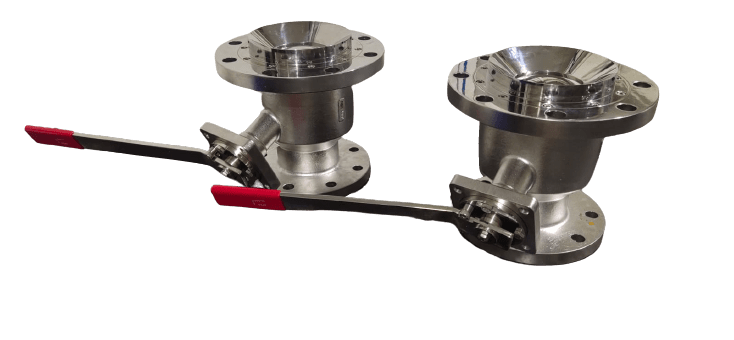

Our Flush Bottom Valves are available in various configurations, offering versatility and a multitude of uses across industries worldwide. They are most commonly employed for fitting into the bottom of vessels, enabling efficient draining of stored materials and facilitating cleaning operations.

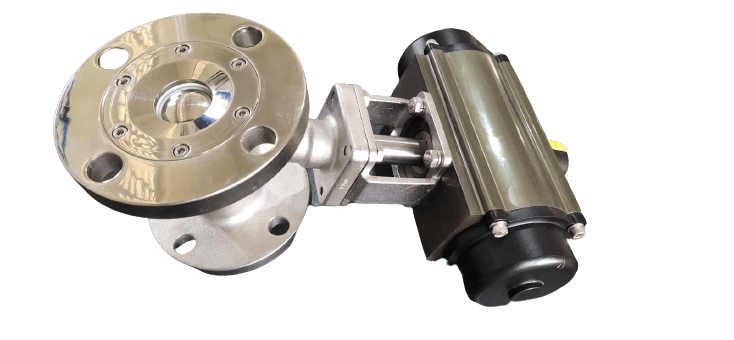

Optimize reactor tank flushing by using JossMin’s range of Flush Bottom Valves – available in standard Ball and upgraded Ball variations. Achieve automated operation for on-off, batching, and controlled flushing by coupling the Valves with our advanced Electro-Pneumatic System.