(Portfolio)

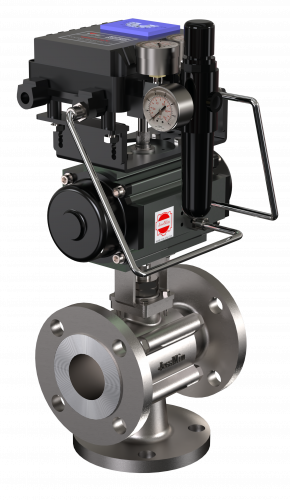

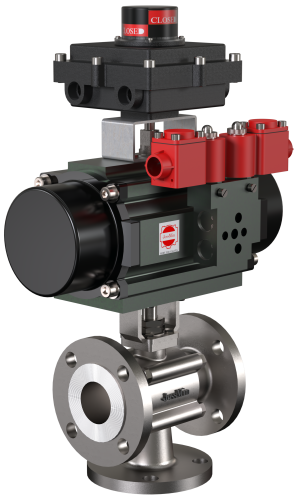

Bore Construction

- T-port Diverter

- L-port Diverter

- Tri-port

- Shut-off

Design Variations

- Seated / Cavity Filled

- Semi Jacketed

- Extended Stem

- Low Emission

Variable End Connections / Rating

- Flanged end / ASME 150#, 300#

- Threaded end – BSPF / NPTF

- Tri Clover end / PN 10, 16